Rust preventative TSA, TSZ, TSAZ

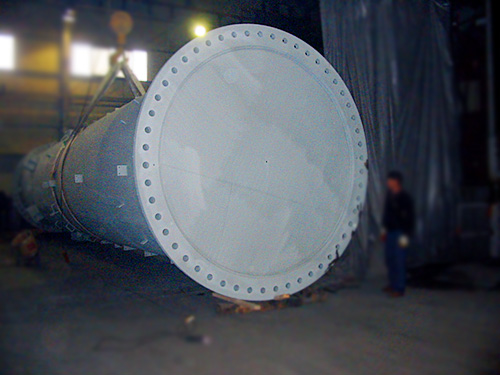

50 ton lift coated with Anti corrosive Zn,Al, zinc aluminum alloy by metalizing has superior rust prevention capability and durability of about 100 years. Especially application to maritime structures and electric power transmission fields are expanding

In case of paint, while it has durability of 5 years or less, Anti corrosive thermal spray has 50 years or more durability.

Excellent rust preventive capability

Preserving ability of 100 years

50 years or more durability

Construction ability satisfying international specifications

| Material | International standard institution | Title |

|---|---|---|

| Zn,Al, Alloys | ISO | [Thermal spraying- Metallic and other inorganic coatings - Zinc, aluminium and their alloys,] ISO 2063 |

| Zn,Al | ISO | [Protection against corrosion of iron and steal in structures] [Zinc and aluminium coatings - Guidelines,]ISO 14713 |

| 85/15 Zinc/Aluminium Alloy | PTS DEPs |

[Thermal Spray Coatings of Aluminium and 85/15 Zinc/Aluminium Alloy] PTS30.48.40.31 [Thermal Spray Coatings of 85/15 Zinc/Aluminium Alloy] DEPs 30.48.31-Gen |

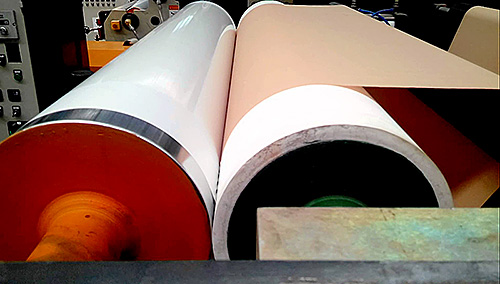

Metalizing of Super large sized Yankee Dryer

This construction equips an installation, operating and coating 3660D*3100L 50 ton-scale drying-roll steroid affiliated or Amorphorus affiliated.

As coating material, 13Cr(HRC40), 30CrSteel(HRC55-60), and cemented carbide (HRC65) are applicable.

Extension of life of Roll

Increase productivity

Increase thermal management efficiency

Reduction effect of CO2 emission

Liquefied ceramic coating

Inorganic ceramic materials are used as anti corrosive film in far-infrared radiation emitting ceramic technology applied in drying, heating and cooking product.

Drying

product

Heating

product

Cooking

product

Mold release coating

When dealing with adhesive material in the production process, the necessity of mold-release is brought up.

To solve this problem

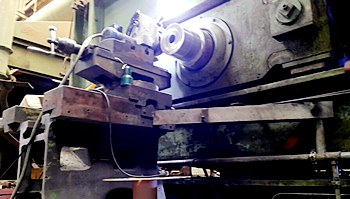

On-site construction to restore emergency failure

Field Construction Tips

Emergency recovery of

Large-sized fan Shahood

Emergency recovery of pressed-roll

Shahood of plywood factory

Field construction application for emergency repair